Biotrickling filter at Salalah Free Zone – Oman

In 2015, Oman government took a start with the development of a new industrial area in Salalah Free zone. This economic zone is holding 212 hectares of industrial sites including labour facilities and has his proper sewage treatment plant. Within the treatment plant, there was also a requirement for an odour control system which Ipec designed and supplied.

Because of the fluctuating occupancy and the specific nature of the sewage from an industrial area, it was expected that the H2S concentration could raise to high levels. Besides H2S, other odour components like ammonia and VOC (Volatile organic compounds) are present.

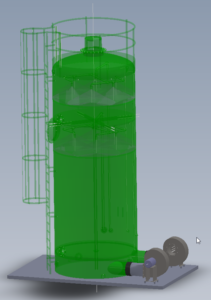

To abate the specific odour components from this industrial water treatment plant, a two-stage odour control system was designed. The OCU is a combination of a biotrickling filter followed by activated carbon as a polishing step. Because of space limitation at site, both steps (biotrickling and activated carbon) are combined in one vessel.

The odour control unit has a flow of about 1000 m³/hour which is created by a direct driven, stainless steel fan. The fan blows the extracted air in the biotrickling filter (BTF) in which water is sprayed over packing material. The packing material functions as a carrier with a high specific surface on which the micro-organisms that remove the odour can grow. These organisms, mainly bacteria, degrade the odourous components while the foul air is flowing through the packing material. The Acidithiobacillus-bacteria are the main group of bacteria used to degrade H2S by converting it into sulfuric acid. Because of the high inlet H2S concentrations, the applied water is not recirculated over the packing but only a single pass is applied. Already after one passage of the water, the conversion of the high amounts of H2S to H2SO4 results in low pH of the water. The bacteria have their optimum pH-working point around 2-3.5, so the removal of H2S will take place in the lower part of the bed.

The odour control unit has a flow of about 1000 m³/hour which is created by a direct driven, stainless steel fan. The fan blows the extracted air in the biotrickling filter (BTF) in which water is sprayed over packing material. The packing material functions as a carrier with a high specific surface on which the micro-organisms that remove the odour can grow. These organisms, mainly bacteria, degrade the odourous components while the foul air is flowing through the packing material. The Acidithiobacillus-bacteria are the main group of bacteria used to degrade H2S by converting it into sulfuric acid. Because of the high inlet H2S concentrations, the applied water is not recirculated over the packing but only a single pass is applied. Already after one passage of the water, the conversion of the high amounts of H2S to H2SO4 results in low pH of the water. The bacteria have their optimum pH-working point around 2-3.5, so the removal of H2S will take place in the lower part of the bed.

In the upper part of the packed bed, the pH will be neutral or slightly decreased which is the ideal conditions for heterotrophic bacteria to grow and to remove VOC from the foul air. In addition, ammonia and amines are removed in the acidic water by formation of a divalent sulfate salt. To overcome the fluctuating quality of the supplied water which is mainly TSE water (treated secondary effluent), a nutrient dosing system is installed to . By PLC-control, the moistening of the biotrickling filter and the dosing of the nutrients is monitored.

To ensure an odour-free exhaust at the stack, the air moves to the top of the vessel were an additional activated carbon bed is installed. Between the biotrickling stage and the carbon bed, a demister package is installed to avoid droplets to move from the below biotrickling spraying system to the carbon bed. The applied activated carbon is water regenerable carbon. This type of carbon is specially selected to remove H2S from the foul air and to convert H2S into H2SO4. After saturation the carbon can be washed out to remove the H2SO4 (regeneration of the carbon) so the carbon can be reused. The carbon vessel is installed with a spraying system so the activated carbon can be regenerated in situ without removal of the carbon.

To ensure an odour-free exhaust at the stack, the air moves to the top of the vessel were an additional activated carbon bed is installed. Between the biotrickling stage and the carbon bed, a demister package is installed to avoid droplets to move from the below biotrickling spraying system to the carbon bed. The applied activated carbon is water regenerable carbon. This type of carbon is specially selected to remove H2S from the foul air and to convert H2S into H2SO4. After saturation the carbon can be washed out to remove the H2SO4 (regeneration of the carbon) so the carbon can be reused. The carbon vessel is installed with a spraying system so the activated carbon can be regenerated in situ without removal of the carbon.

The regeneration of the activated carbon is completely automated by PLC control, so no presence of labour is required during regeneration. To even enhance the performance further and to ensure a longer life time of the activated carbon, a special grade of water regenerable carbon was selected. This particular type of carbon has an adsorption capacity of more than 300g/liter. This carbon with a high adsorption capacity must allow to have less frequent shut-down for regeneration which will result in an even higher availability of the odour control unit.