Odour Control unit Sabah Al Ahmad Sea View City, Kuwait.

A multi-billion-dollar city has been built in Kuwait, close to Saudi Arabian borders, and is set to become a metropolis of 250,000 people. Sabah Al Ahmad Sea City, which will spread across an area the size of Manhattan, is named after Sabah Al Ahmad, the 86-year-old emir of Kuwait, who came to power in 2006.

A multi-billion-dollar city has been built in Kuwait, close to Saudi Arabian borders, and is set to become a metropolis of 250,000 people. Sabah Al Ahmad Sea City, which will spread across an area the size of Manhattan, is named after Sabah Al Ahmad, the 86-year-old emir of Kuwait, who came to power in 2006.

Odour Control Units were foreseen to be installed in the proposed pump station to keep the area free of foul odour. IPEC NV was collectively selected to design, manufacture, supply and commission the odour control system.

Odour Control Units were foreseen to be installed in the proposed pump station to keep the area free of foul odour. IPEC NV was collectively selected to design, manufacture, supply and commission the odour control system.

An odour control system with water regenerable activated carbon was designed by IPEC NV to handle the air flow capacity of 13350 m3/hr with an inlet H2S range of 100ppm and peaks up to 250ppm.

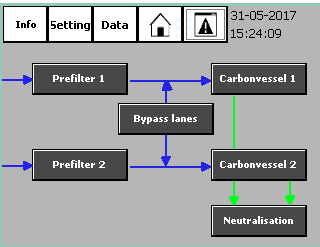

A complete identical working/standby system including dual fans, dual prefilters and dual carbon vessels was installed. Extraction fans were installed in soundproof cabinets for noise reduction.

A prefilter with automated cleaning facility is located upstream of the fans in order to filter dirt and dust before the air enters the activated carbon system. A dual bed activated carbon, vertical vessel was designed to handle the desired flow.

A High quality FRP fan was selected and the same was enclosed in a noise suppressing cabinet. Control Instruments such as H2S transmitters, delta pressure transmitters, pressure switches,… were installed to operate the system as a fully automated and stand-alone unit with minimum attendance required. By means of automated water supply and drain valves, the carbon can be regenerated automatically based on the control philosophy which is integrated in the PLC.

A complete standalone, control cabinet was selected. The LCP is provided with an air-conditioning system as the installation was in a desert area where the temperatures can reach up to an extreme of about 50-55°C in peak summer.

By PLC and HMI, an intuitive operation of the odour control unit is achieved. The PLC has on-board Modbus for remote communication with the main Scada-room. The unit is completely automated in order to reduce the operator interventions to the minimum. The fans are automatically switching-over every 24 hours.

By PLC and HMI, an intuitive operation of the odour control unit is achieved. The PLC has on-board Modbus for remote communication with the main Scada-room. The unit is completely automated in order to reduce the operator interventions to the minimum. The fans are automatically switching-over every 24 hours.

Based on the readings of H2S at the inlet and the outlet of the OCU, the need for regeneration of the carbon can be detected and is automatically initiated during the following night. By delta pressure control, the prefilter clogging is detected and in situ cleaning of the prefilter cassette is initiated.